- September 27, 2021

- 145 views

- 0 Comments

The dust was tested as combustible, was abrasive and included fine plastic dust, a buffing compound and materials from the buffing and polishing wheels. The customer had been collecting the dust from the process in their existing cartridge dust collector, but the sticky and clumpy material from the buffing/polishing would pack into the pleats and not release during pulse cleaning, resulting in poor system performance and shortened filter life.

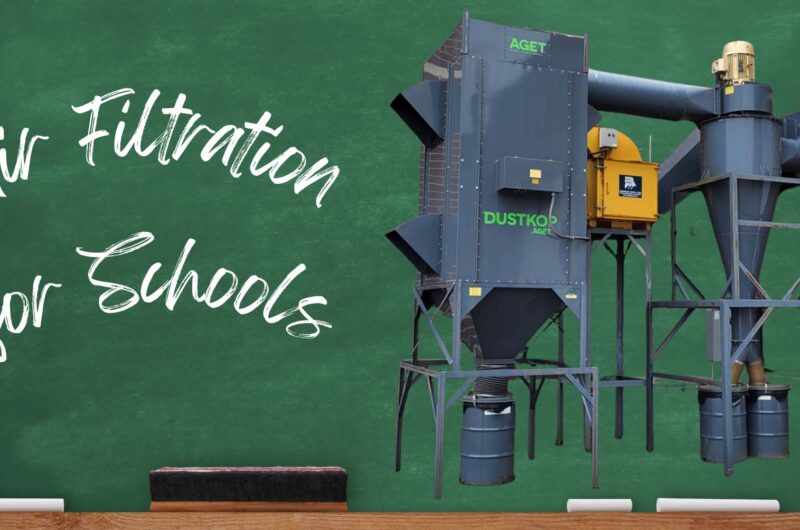

The solution was to design, supply and install an Aget Manufacturing model 90SN70-D2 DustKop cyclone dust collector with a model FT-88-D1 DustKop shaker-type after filter which was connected to the existing duct system with some modifications. The Aget SN cyclone has a nominal removal efficiency of 92-95% at 7 microns, so the majority of the dust/material collected from the process equipment would be removed from the airstream prior to the air being introduced into the after filter. The Aget model FT shaker-type after filter is equipped with a beane bag polyester filter tubes that provide 95% efficiency on particulate 1 micron and above and are designed for tacky, difficult substances. The shaker cleaning system activates upon system shut down, helping to knock any collected dust into the hopper and drum assembly for easy removal.

Pressure relief panels are installed on both the cyclone and the after filter housing and a Rembe Q-Flap NX NOVEx inline back blast valve is installed on the inlet duct the appropriate distance from the cyclone inlet. The Rembe valve has both a flap position sensor and a dust accumulation sensor that communicate valve condition with the control panel, ensuring that the system is completely shut down in the event of an explosion within the collector. The Rembe valve is ATEX certified and meets or exceeds NFPA standard 69 requirements and is suitable for ST1 and ST2 applications.

The system works great and removing the buffing and polishing process has helped to improve the performance and filter life of the existing cartridge collector. The expectation is that the filter tubes in the Aget model FT unit will provide many years of life with minimal maintenance.

Please contact 3B Air Systems today at Call us at 440 610 9993 or email at [email protected] to see if we can help with your industrial air filtration, dust collection, vacuum, process air or ventilation needs.